How Does a Steerable Lift Axle Work? Everything You Should Know About a Steerable Lift Axle

July 29, 2022

Traditional non-steerable axles may not be the answer to your payload challenges. Tight corners expose them to tremendous wear and tear, and lifting them may overload the remaining axles. Steerable lift axles can provide a lasting solution to this problem. If you're considering maximizing your payload without exerting too much pressure on your axles and rubbing state laws the wrong way, you could go for steerable lift axle solutions.

What Is a Steerable Lift Axle?

Steerable lift axles are added onto trucks or trailers to increase their payload capacity. Unlike traditional lift axles, steerable axles have wheels that can swivel and follow the path of least resistance. Increasing your payload capacity - and possibly maximizing revenues - may not be the only reason to retrofit your trailers and trucks with a steerable lift axle.

The ever-changing patchwork of bridge laws and weight limits across states in the US and Canada may lead you to introduce auxiliary lift axles to your fleets. The laws vary and keep changing from time to time and from one state to the other, and it may be difficult to keep up with them. Whichever the reason, you may do well fitting them to your vehicles.

How Does a Steerable Lift Axle Work on a Trailer or Truck?

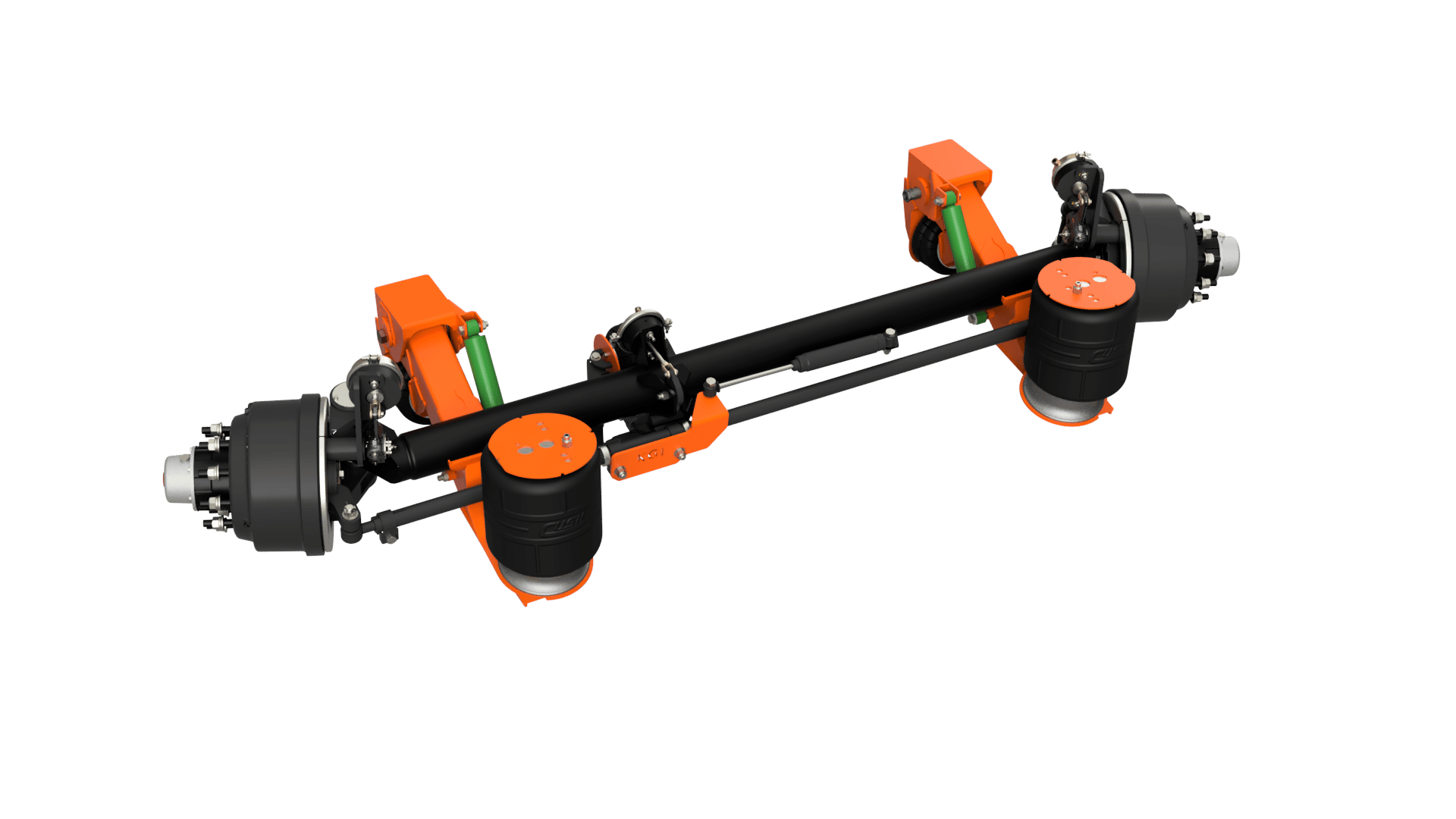

Steerable lift axles may appear a simple phenomenon – we often see trucks with these axles cruising along the interstates. A complex piece of engineering goes into the design and process of fitting them under the trucks.

To begin with, their wheels need to be able to swivel and self-steer so they can choose the path of the least resistance, reducing wear and tear to the axles. To achieve this feat, engineers have to fit them at an appropriate location most immediately before or after the drive axle. This clever positioning reduced dragging or scrubbing along corners while still distributing the payload weight properly and meeting compliance requirements.

Pros and Cons of Steerable Lift Axle

A closer look at the pros and cons of a steerable lift axle will put you at a point of information and help you decide whether to install them on your fleets. Here's a rundown of the pros and cons of these innovative auxiliary axles:

Pros

- Can increase payload capacity: Steerable lift axles allow you to pack more load onto your truck because they give extra support to the fixed axles.

- Reduce wear and tear: They reduce potential damage to the wheels, tires, and chassis components, which can be brought about by scrubbing or dragging the tires of non-steerable auxiliary axles around sharp bends.

- Proper distribution of weight along the chassis: Steerable lift axles help in weight distribution, balancing it evenly along the chassis, and reducing wear and tear on the fixed axles.

- Help meets state compliance requirements: Weight and bridge requirements in different states keep changing, and the best way to stay abreast is by fitting steerable lift axles under your trucks.

Cons

- Leads to the increased weight of the chassis: Adding one or more steerable lift axles to the chassis increases its weight which may lead to more fuel consumption and may get you into trouble with weight and bridge laws in your state.

- Complex to install: It needs complex engineering to know where to fit those steerable lift axles.

- Can cause problems with state regulations: Retrofitting your trucks with these auxiliary axles may increase the weight of the chassis, and the overall weight of the vehicle, which may, in turn, exceed state requirements.

Steerable lift axles can help solve the potential damage to chassis components, tires, and wheels brought about by scrubbing or dragging around sharp bends. They distribute the vehicle weight more evenly, balancing the truck. If you are interested in a custom-engineered steerable lift axle, contact the heavy-duty suspension experts at Cush Suspensions!