What Is A Single Point Suspension System?

February 28, 2022

A single point suspension system is a type of trailer suspension that allows the entire weight of cargo to be supported by one center single pivot. Generally, this system has mechanical loading at each wheel, allowing the axle to rise and lower based on the load it supports.

The advantages of a single point suspension include safe loading and unloading (because there is mechanical advantage), stability while driving down highways (higher roll stability than 4 spring or air ride), more stable for end dumps as they can keep both axles on the ground, and more axle articulation travel than typical suspensions because the suspension is not load limited for its travel due to articulation travel. Since these units can carry heavy loads with tandem axles, they also have higher weight limits than your standard trailer.

A single point suspension system is an advanced truck trailer suspension system used on heavier loads. A traditional suspension has multiple shafts with hangers, mounts and brackets which are mounted to the chassis of a heavy trailer or semi-trailer. The load rides on rubber tires at each corner of the trailer that connect to the hub via a metal axle.

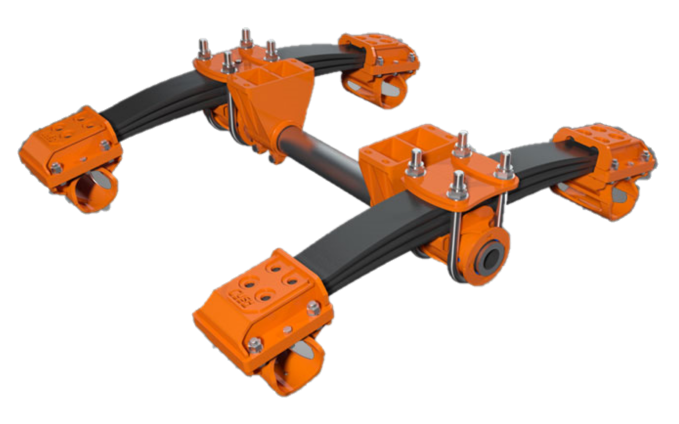

The single point suspension system has a center trunnion tube beam which is attached to the semi-trailer to transfer the load. This also results in a reduction of un-sprung mass. The axle beam is mounted on swivel points at each end (similar to the pivot point of a seesaw) that are attached to the trailer body.

Single point suspension system benefits

The single point suspension allows for greater weight distribution between axles with up to 25% more payload than with four-axle trailers and better stability. This means that vehicles are better able to handle sharp or severe directional changes without losing stability. The vehicle also has less body roll in tight corners which results in improved safety and comfort for drivers. Due to the lack of suspension components, single point suspension systems result in reduced total cost of ownership over the life of a trailer since fewer components need to be replaced.

The absence of suspension components also means less corrosion – thus increasing the useful life – and there is no risk of leaves or mud building up in suspension springs which can impair performance and cause accidents. The large-scale use of single point suspension systems will result in a reduced environmental impact by reducing fuel consumption and greenhouse gas emissions due to their ability to carry heavier loads.

The first concepts for this type of suspension system were patented in the early 20th century but it was not until after World War II that they started gaining wider acceptance. Today, there are many types of single point suspension systems on the market designed to suit different vehicles, requirements and types of load.

How Does A Single Point Suspension Work?

Single point suspensions are often referred to as SPS. The SPS consists of the center mount, also known as the trunnion tube, the spring pack on each side for carrying the load, the center bushing that the spring pack pivots on, the axle connections that connect the axle to the spring pack. The tandem axle setup is connected to each other on each side with a spring pack, mechanical loading pivots the loading from the heavy loaded side to the off load side and rotates the suspension until equilibrium occurs because of the load balancing effect of the center single-point connection.

How Do You Maintain A Single Point Suspension?

Maintenance of a SPS includes:

- Checking for wear and damage: bushings, singlepoint springs, axle connections

- Checking for axle alignment issues

The benefits of a single point suspension include:

- Enhanced safety by reducing sway, which can lead to crashes

- Increased stability and reduced risk of damage to freight

Custom Suspension Work For Your Needs

Contact Cush Suspensions for any and all questions regarding your trucking needs. They have the right team to tackle your custom job!